Our vision is to simplify manufacturing complexities and shorten project cycles for our customers through our rich manufacturing and design experience. Our success is defined by our customers' success

Quick Links

Our Custom Sheet Metal Services

Laser Cutting

Laser cutting in sheet metal processing provides precise, high-speed cutting with minimal material waste, delivering exceptional accuracy and efficiency.

Metal Stamping

Metal stamping in sheet metal processing involves pressing or punching metal sheets into specific shapes and designs with high precision and efficiency.

Metal Bending

Metal bending in sheet metal processing involves shaping metal sheets by applying force to achieve precise angles and curves.

Materials

Sheet metal materials

Aluminum: AL5052-H32, AL6061, AL7075

Stainless Steel: SS303, SS304, SS316

Steel: DC01 Carbon steel, Carbon tool steel SK7, 1018 steel, 1020 steel, Galvanized steel, Cold rolled steel, Hot rolled steel

Brass: Copper:1100/110 Copper

Sheet Metal Tolerance

| With Drawing | Without Drawing | |

| Linear Dimension | +/- 0.1 mm

+/- 0.004 inch ISO 2768-mk | ISO 2768 Course |

| Bend to Hole | +/- 0.2 mm

+/- 0.008 inch ISO 2768-mk | ISO 2768 Course |

| Angular | +/- 0.5 degree | ISO 2768 Course |

The tolerances specified here represent the ideal minimums. Depending on the manufacturing process, material choice, or part geometry, broader tolerances may be required.

Surface Finishing Options for custom parts

Surface Finishing Options for custom parts meet your diverse surfacetreatment needs, enhancing both the durability and aesthetics of yourcomponents.Our advanced finishing techniques, including powdercoating, anodizing, and plating, provide superior protection againstcorrosion, wear, and environmental factors. These finishes also offerimproved performance and an attractive appearance, ensuring yourproducts meet the highest quality standards.

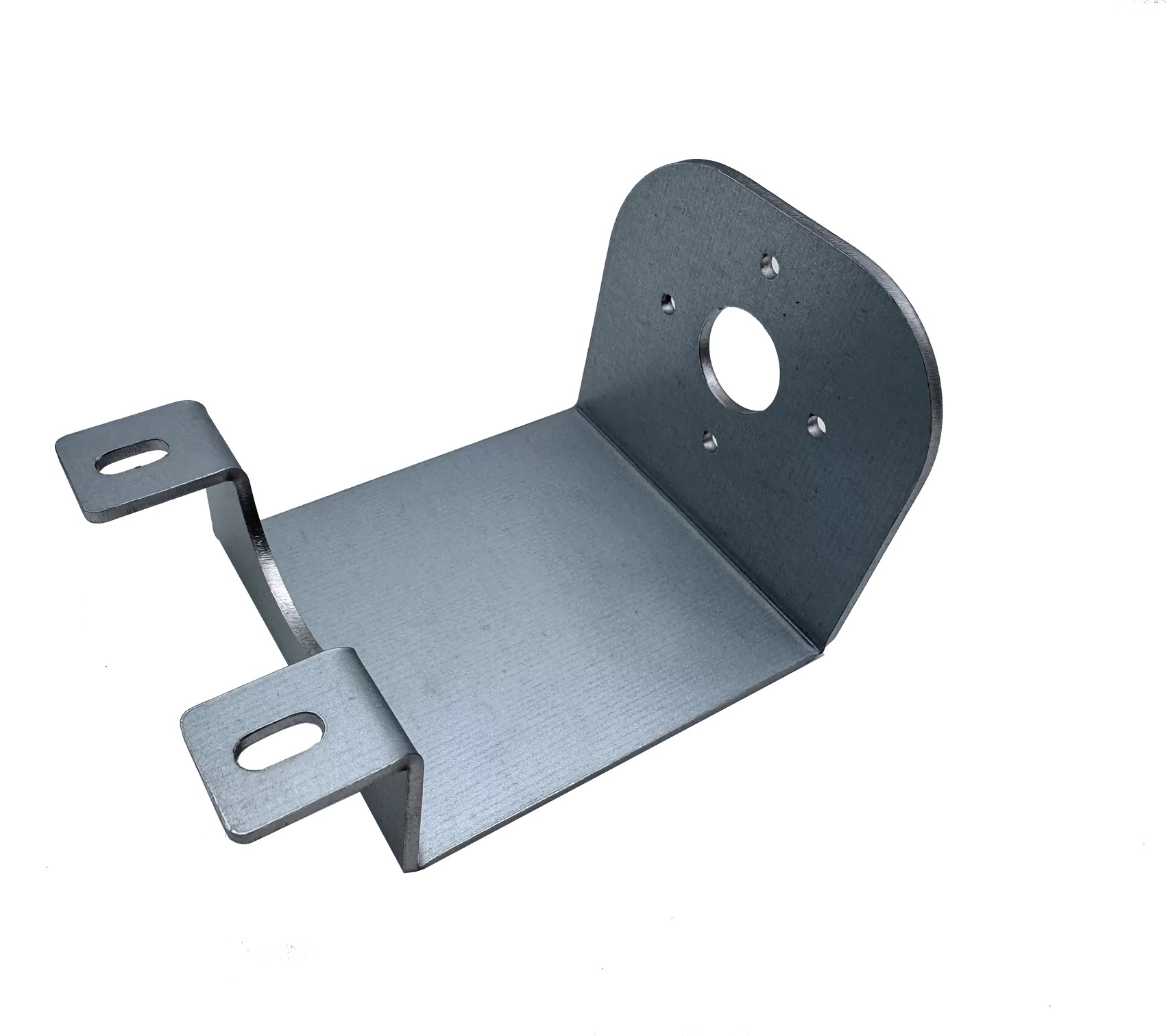

91mns Tech Sheet Metal Samples

Why Choose 91mns Tech For Sheet Metal Fabrication?

Wide range of metal sheet services with diverse machining techniques.

Competitive pricing.

Fast processing speeds.

Consistent quality ensured by advanced Zeiss CMM equipment.

Experienced team of engineers.

Worldwide shipping guarantee.

Sheet Metal FAQs

Q How does metal bending affect the final product?

Metal bending shapes the metal sheet by applying force to achieve desired angles and curves. This process is crucial for creating components that require specific geometric features and ensures that parts fit together correctly in the final assembly.

Q What materials are commonly used in sheet metal processing?

Common materials include steel, aluminum, stainless steel, and copper. The choice of material depends on the required strength, corrosion resistance, weight, and cost considerations for the application.

Q What are some common surface finishing options for sheet metal?

Surface finishing options include powder coating, anodizing, plating, and painting. These finishes improve the metal's appearance, durability, and resistance to environmental factors like corrosion and wear.

Q How do you handle issues with warping or distortion during bending?

Warping or distortion can be minimized by using proper tooling, controlling the bending parameters, and selecting the appropriate material thickness. Pre-bending techniques and adjusting the die or punch can also help manage these issues.

Q How does sheet metal processing impact overall product cost?

The cost is influenced by factors such as material type, processing complexity, and production volume. Efficient processing techniques, such as laser cutting for precision and stamping for high volumes, can help optimize costs. Additionally, choosing cost-effective materials and finishes can further impact the overall product cost.

Talk to Us About Your New Project!

Get a Quote