Our vision is to simplify manufacturing complexities and shorten project cycles for our customers through our rich manufacturing and design experience. Our success is defined by our customers' success

Quick Links

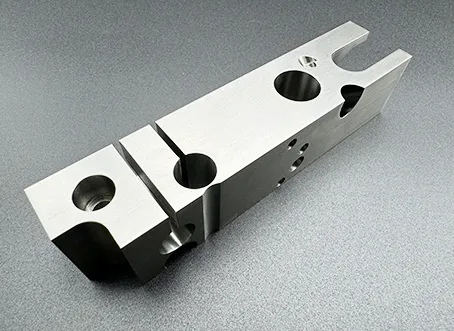

CNC Milling

Metals

Aluminum

Types: 6061-T6, 7075-T6, 6061,7075,7050, 2024, 5052, 6063, MIC6

Finishing Options: Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing

Colors: /

Properties: Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

See All

Brass

Types: 274, 280, 360 Brass

Finishing Options: Media Blasting

Colors: /

Properties: Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

See All

Bronze

Types: 932 Bearing Bronze

Finishing Options: Media Blasting, hand polishing

Colors: /

Properties: Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

See All

Copper

Types: Copper 101,110,103

Finishing Options: Media Blasting, hand polishing

Colors: /

Properties: Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

See All

Stainless Steel

Types: 303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60

Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Colors: /

Properties: Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

See All

Steel

Types: 4140, 4130, A514, 4340, 1018, 1020,1045, 1215

Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Colors: /

Properties: Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

See All

Titanium

Types: Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

Finishing Options: Media Blasting, Passivation, Powdercoating

Colors: /

Properties: Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

See All

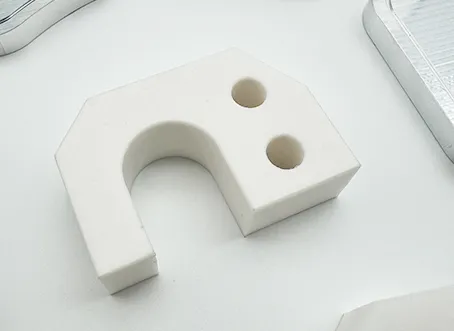

Plastics

ABS

Types: /

Finishing Options: /

Colors: natural(beige),black

Properties: ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

See All

Acrylic/PMMA

Types: /

Finishing Options: hand polishing

Colors: clear, matt

Properties: PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

See All

Delrin(POM)

Types: 150, AF (13% PTFE Filled), 30% Glass Filled

Finishing Options: /

Colors: black,white

Properties: POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

See All

Garolite G-10

Types: /

Finishing Options: /

Colors: green,yellow

Properties: Garolite G-10 has high strength, rigidity, impact resistance, and is an excellent electrical insulating material. It is commonly used in the aerospace, electronics, and automotive industries.

See All

HDPE

Types: /

Finishing Options: /

Colors: black,white

Properties: HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

See All

Nylon

Types:

PA(Nylon)

PA6 (Nylon)+GF15

PA6 (Nylon)+GF30

PA66

Finishing Options: /

Colors: black,white,natural(Beige)

Properties: Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

See All

PEEK

Types: /

Finishing Options: /

Colors: natural(beige),Black

Properties: PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

See All

Polycarbonate

Types: /

Finishing Options: Vapor polishing

Colors: Clear, black,white

Properties: Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

See All

Polypropylene

Types: /

Finishing Options: /

Colors: White, black

Properties: Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

See All

PTFE

Types: /

Finishing Options: /

Colors: black,white

Properties: PTFE is known for its outstanding chemical resistance and low friction, making it perfect for non-stick coatings and gaskets.

See All

UHMW

Types: /

Finishing Options: /

Colors: black,white

Properties: UHMW (Ultra-High Molecular Weight Polyethylene) is a versatile material known for its exceptional wear resistance, low friction coefficient, chemical resistance, and excellent impact resistance. It finds widespread applications in industries such as logistics, packaging, food processing, automotive, and medical.

See All

Ultem

Types: /

Finishing Options: /

Colors: Naturally translucent amber color, frosted when machined

Properties: ULTEM is a high-temperature, high-strength thermoplastic material known for its excellent fatigue resistance, chemical resistance, superior insulation properties, and high rigidity. It finds extensive applications in industries such as aerospace, medical, electronics, automotive.

See All

CNC Machining Tolerance

| Metals, ULTEM, And PEEK with Drawing | Other Plastics with Drawing | No Drawing | |

| Nominal Iength | +/-0.01 mm +/-0.0003 inch | +/-0.05 mm +/-0.002 inch | ISO 2768 Medium |

| Hole Diameters (Not Reamed) | +/-0.01 mm +/-0.0003 inch | +/-0.05 mm +/-0.002 inch | ISO 2768 Medium |

| Shaft Diameters | +/-0.005 mm +/-0.0002 inch | +/-0.05 mm +/-0.002 inch | ISO 2768 Medium |

Surface Finishing Options for custom parts

Surface Finishing Options for custom parts meet your diverse surfacetreatment needs, enhancing both the durability and aesthetics of yourcomponents.Our advanced finishing techniques, including powdercoating, anodizing, and plating, provide superior protection againstcorrosion, wear, and environmental factors. These finishes also offerimproved performance and an attractive appearance, ensuring yourproducts meet the highest quality standards.

Why Choose 91mns Tech For CNC Milling?

Wide range of CNC services with diverse machining techniques.

Competitive pricing.

Fast processing speeds.

Consistent quality ensured by advanced Zeiss CMM equipment.

Experienced team of engineers.

Worldwide shipping guarantee.

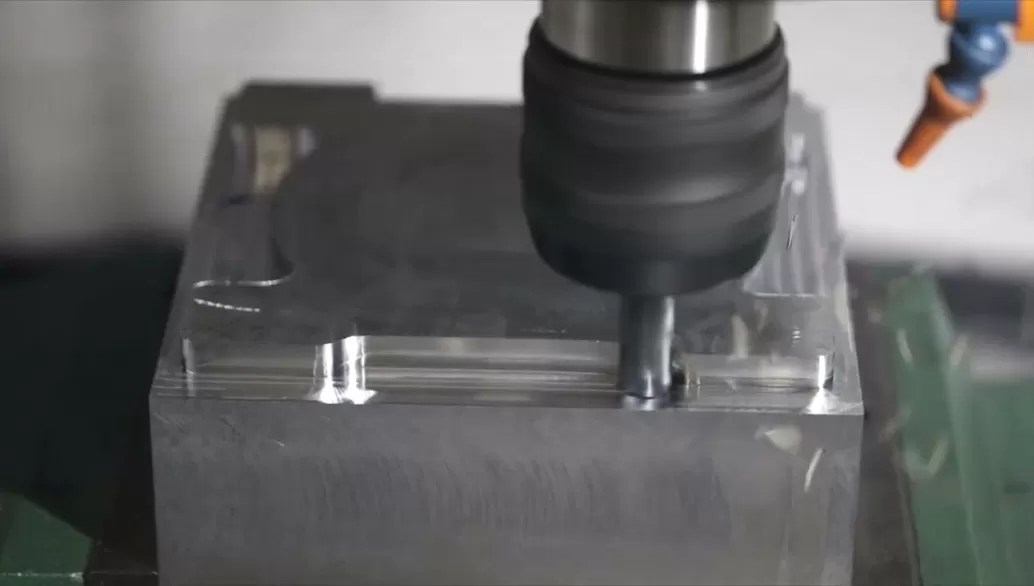

About the CNC Milling Process

3-axis CNC machining

What is 3-axis CNC machining?

3-axis CNC machining is a computer-controlled manufacturing process where the cutting tool moves in three linear axes (X, Y, and Z) to remove material from a workpiece.

How 3-axis CNC machining work?

the workpiece remains stationary while the cutting tool moves along the three axes to perform operations such as milling, drilling, and cutting. The CNC machine is programmed using a CAD/CAM software, which translates the design into precise movements of the tool

Suitable for What Kind of Part?

3-axis CNC machining is suitable for parts with simple geometries that can be accessed from one direction. It is ideal for creating flat surfaces, slots, holes, and pockets, making it commonly used in industries such as aerospace, automotive, and manufacturing for parts like brackets, plates, and basic enclosures.

Advantages

Cost-Effective: Typically less expensive than more complex multi-axis machines.

Ease of Use: Easier to program and operate compared to 4-axis or 5-axis machines.

Quick Setup: Faster setup times for simpler parts.

Precision: Capable of achieving high accuracy and repeatability for straightforward tasks.

Disadvantages

Limited Complexity: Unable to machine complex geometries or parts requiring undercuts and intricate features.

Manual Repositioning: May require multiple setups and manual repositioning for certain shapes, increasing production time and potential for errors.

Restricted Efficiency: Less efficient for parts that need multi-sided machining, leading to longer production times compared to multi-axis CNC machines.

Overall

3-axis CNC machining is a versatile and cost-effective solution for many manufacturing needs, though it is best suited for simpler parts and may not be adequate for more complex projects.

4-Axis CNC Machining

In What?

4-axis CNC machining is an advanced manufacturing process where the cutting tool moves in three linear axes (X, Y, and Z) plus an additional rotational axis (usually around the X-axis, called the A-axis) to remove material from a workpiece.

How?

In 4-axis CNC machining, the workpiece can be rotated around the A-axis, allowing for additional access and flexibility compared to 3-axis machining. This rotation enables the tool to approach the workpiece from different angles, reducing the need for multiple setups and manual repositioning. The machine is programmed using CAD/CAM software, which controls the precise movements of both the linear and rotational axes.

Suitable for What Kind of Part?

4-axis CNC machining is suitable for parts with more complex geometries that require machining on multiple sides without manual repositioning. It is ideal for components such as camshafts, turbine blades, and intricate carvings, commonly used in aerospace, automotive, and medical industries.

Advantages

Increased Complexity: Can handle more complex geometries and intricate designs compared to 3-axis machines.

Fewer Setups: Reduces the need for multiple setups, improving efficiency and reducing production time.

Enhanced Precision: Allows for more precise machining of features that require access from different angles.

Better Surface Finish: Can achieve smoother finishes on parts with curved surfaces or contours.

Disadvantages

Higher Cost: Generally more expensive to purchase and maintain than 3-axis machines.

Complex Programming: Requires more advanced programming skills and software, which can increase the initial setup time and cost.

Limited to One Rotational Axis: While more versatile than 3-axis machining, it is still limited compared to 5-axis machines, which can handle even more complex geometries.

Overall

4-axis CNC machining offers a good balance between complexity and cost, making it suitable for a wide range of parts that benefit from additional rotational access and reduced setups, but it may not be sufficient for the most complex machining tasks.

5-Axis CNC Machining

In What?

5-axis CNC machining is an advanced manufacturing process where the cutting tool moves in three linear axes (X, Y, and Z) and two additional rotational axes (typically around the X and Y axes, called the A and B axes) to remove material from a workpiece.

How?

In 5-axis CNC machining, the workpiece can be rotated around multiple axes, allowing the cutting tool to approach the workpiece from virtually any angle. This provides the highest level of flexibility and precision, enabling the machining of highly complex and intricate parts in a single setup. The machine is programmed using sophisticated CAD/CAM software, which controls the precise movements of both the linear and rotational axes.

Suitable for What Kind of Part?

5-axis CNC machining is suitable for parts with highly complex geometries that require machining on multiple sides and angles without manual repositioning. It is ideal for components such as turbine blades, aerospace structures, medical implants, and intricate molds, commonly used in aerospace, automotive, medical, and mold-making industries.

Advantages

Complex Geometries: Capable of machining the most complex parts with intricate features and undercuts.

Single Setup: Can machine all sides of a part in a single setup, reducing production time and the risk of errors.

Precision and Accuracy: Offers the highest level of precision and accuracy, especially for parts requiring tight tolerances.

Improved Surface Finish: Achieves superior surface finishes due to the ability to approach the workpiece from optimal angles.

Efficiency: Increases efficiency and reduces lead times by minimizing the number of setups and manual interventions.

Disadvantages

High Cost: Significantly more expensive to purchase, maintain, and operate than 3-axis and 4-axis machines.

Complex Programming: Requires advanced programming skills and more sophisticated software, increasing the initial setup time and cost.

Training Requirements: Operators and programmers need extensive training to effectively use the machine, which can add to the overall cost.

Overall

5-axis CNC machining offers unparalleled capabilities for producing complex and high-precision parts, making it ideal for industries where intricate designs and tight tolerances are crucial. However, the higher cost and complexity of operation make it best suited for applications where these advanced capabilities are essential.

Learn More About CNC Machining

CNC Milling FAQs

Q What is CNC milling?

CNC milling is a computer numerical control machining technique that involves cutting and shaping workpieces using automated machine tools and pre-programmed instructions. CNC milling achieves precise machining of workpieces by controlling the movement of the cutting tool and workpiece along multiple axes.

Q How is CNC milling different from conventional milling?

Compared to traditional manual or mechanical milling, CNC milling offers higher levels of automation and precision. CNC milling uses computer control systems to guide the movement of the cutting tool and workpiece, allowing for more complex shapes and improved repeatability. In contrast, conventional milling typically requires manual operation and human control.

Q What materials can be processed with CNC milling?

CNC milling can be used to process various materials, including metals (such as aluminum, steel, stainless steel), plastics, wood, composite materials, and more. The machining process and tool selection may vary for different materials, requiring appropriate machining parameters and process considerations based on specific material characteristics.

Q How are the axes of a CNC milling machine defined?

Common CNC milling machines typically have three main axes: X-axis, Y-axis, and Z-axis. The X-axis represents horizontal movement, the Y-axis represents vertical movement, and the Z-axis represents vertical movement. More advanced milling machines may include additional rotational axes (such as A-axis and B-axis) for multi-axis machining.

Start Your New Project!

Get a Quote