Our vision is to simplify manufacturing complexities and shorten project cycles for our customers through our rich manufacturing and design experience. Our success is defined by our customers' success

Quick Links

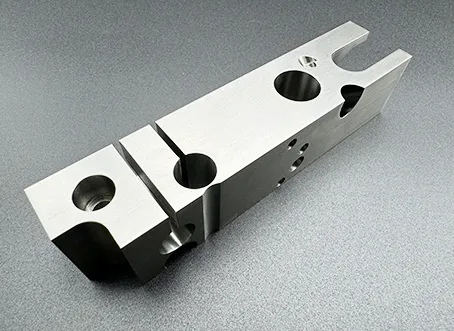

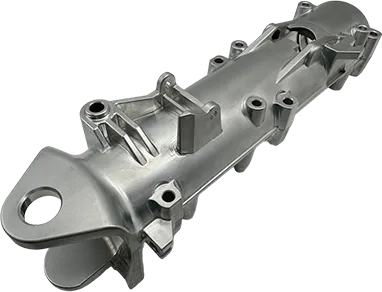

Our CNC Machining Services

With CNC machining cutting tooling as a brush, programmed toolpaths can be transformed into art.

CNC turning excels in producing cylindrical products with high surface finish, aesthetically pleasing appearance, precise tolerances, and rapid machining speeds

EDM (Electrical Discharge Machining) is a process that uses electrical discharges to shape hard metals into intricate and precise components.

0-0H

Quotes

0 day

Lead time

0.000mm

Tolerances

0 PC

MOQ

CNC Machining Materials

Metals

Aluminum

Types: 6061-T6, 7075-T6, 6061,7075,7050, 2024, 5052, 6063, MIC6

Finishing Options: Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing

Colors: /

Properties: Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

See All

Brass

Types: 274, 280, 360 Brass

Finishing Options: Media Blasting

Colors: /

Properties: Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

See All

Bronze

Types: 932 Bearing Bronze

Finishing Options: Media Blasting, hand polishing

Colors: /

Properties: Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

See All

Copper

Types: Copper 101,110,103

Finishing Options: Media Blasting, hand polishing

Colors: /

Properties: Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

See All

Stainless Steel

Types: 303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60

Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Colors: /

Properties: Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

See All

Steel

Types: 4140, 4130, A514, 4340, 1018, 1020,1045, 1215

Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Colors: /

Properties: Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

See All

Titanium

Types: Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

Finishing Options: Media Blasting, Passivation, Powdercoating

Colors: /

Properties: Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

See All

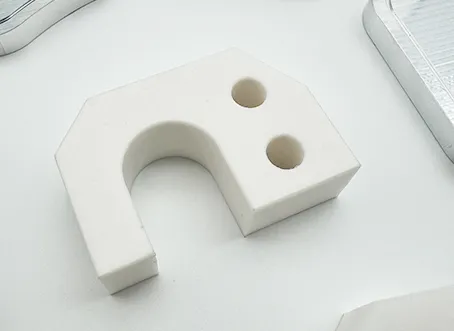

Plastics

ABS

Types: /

Finishing Options: /

Colors: natural(beige),black

Properties: ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

See All

Acrylic/PMMA

Types: /

Finishing Options: hand polishing

Colors: clear, matt

Properties: PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

See All

Delrin(POM)

Types: 150, AF (13% PTFE Filled), 30% Glass Filled

Finishing Options: /

Colors: black,white

Properties: POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

See All

Garolite G-10

Types: /

Finishing Options: /

Colors: green,yellow

Properties: Garolite G-10 has high strength, rigidity, impact resistance, and is an excellent electrical insulating material. It is commonly used in the aerospace, electronics, and automotive industries.

See All

HDPE

Types: /

Finishing Options: /

Colors: black,white

Properties: HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

See All

Nylon

Types:

PA(Nylon)

PA6 (Nylon)+GF15

PA6 (Nylon)+GF30

PA66

Finishing Options: /

Colors: black,white,natural(Beige)

Properties: Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

See All

PEEK

Types: /

Finishing Options: /

Colors: natural(beige),Black

Properties: PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

See All

Polycarbonate

Types: /

Finishing Options: Vapor polishing

Colors: Clear, black,white

Properties: Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

See All

Polypropylene

Types: /

Finishing Options: /

Colors: White, black

Properties: Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

See All

PTFE

Types: /

Finishing Options: /

Colors: black,white

Properties: PTFE is known for its outstanding chemical resistance and low friction, making it perfect for non-stick coatings and gaskets.

See All

UHMW

Types: /

Finishing Options: /

Colors: black,white

Properties: UHMW (Ultra-High Molecular Weight Polyethylene) is a versatile material known for its exceptional wear resistance, low friction coefficient, chemical resistance, and excellent impact resistance. It finds widespread applications in industries such as logistics, packaging, food processing, automotive, and medical.

See All

Ultem

Types: /

Finishing Options: /

Colors: Naturally translucent amber color, frosted when machined

Properties: ULTEM is a high-temperature, high-strength thermoplastic material known for its excellent fatigue resistance, chemical resistance, superior insulation properties, and high rigidity. It finds extensive applications in industries such as aerospace, medical, electronics, automotive.

See All

CNC Machining Tolerance

| Metals, ULTEM, And PEEK with Drawing | Other Plastics with Drawing | No Drawing | |

| Nominal Iength | +/-0.01 mm +/-0.0003 inch | +/-0.05 mm +/-0.002 inch | ISO 2768 Medium |

| Hole Diameters (Not Reamed) | +/-0.01 mm +/-0.0003 inch | +/-0.05 mm +/-0.002 inch | ISO 2768 Medium |

| Shaft Diameters | +/-0.005 mm +/-0.0002 inch | +/-0.05 mm +/-0.002 inch | ISO 2768 Medium |

Surface Finishing Options for custom parts

Surface Finishing Options for custom parts meet your diverse surfacetreatment needs, enhancing both the durability and aesthetics of yourcomponents.Our advanced finishing techniques, including powdercoating, anodizing, and plating, provide superior protection againstcorrosion, wear, and environmental factors. These finishes also offerimproved performance and an attractive appearance, ensuring yourproducts meet the highest quality standards.

Download our CNC design Guide!

Learn how to reduce cost and Lead time in your projects, streamline the design and machining process, and make your projects run smoother.

DownloadCNC Machining Parts Made By 91 MNS

Learn More About CNC Machining

CNC Machining FAQs

Q What does CNC stand for?

CNC stands for Computer Numerical Control. It refers to the use of computer-controlled machinery that operates cutting tools and materials based on pre-programmed instructions, it calls subtractive Manufacturing as well.

Q What are the advantages of CNC machining?

CNC machining offers advantages such as high precision, repeatability, efficiency, and flexibility. It can achieve complex shapes, work with various materials, and enable high-volume production in a short time.

Q Which materials can be used in CNC machining?

CNC machining is suitable for a variety of materials, including metals (such as aluminum, steel, stainless steel), plastics, wood, and composite materials. The specific machinable materials depend on the capabilities of the machine and the suitability of the cutting tools.

Q What are the applications of CNC machining?

CNC machining is widely used in various industries, including automotive manufacturing, aerospace, electronics, medical devices, mold making, furniture manufacturing, and more. It can be used to produce parts, prototypes, molds, and other products.

Q How many CNC machines do you have?

We have 16 CNC machining centers, 2 large-sized CNC milling machines, and 2 CNC lathes.

Q Do you offer Quick-Turn CNC Machining?

91MNS is a small to medium-sized factory with a highly experienced engineering team. We offer high flexibility and can achieve leadtime as fast as 1 day. Our focus is centered around serving our customers.

Talk to Us About Your New Project!

Get a Quote