Our vision is to simplify manufacturing complexities and shorten project cycles for our customers through our rich manufacturing and design experience. Our success is defined by our customers' success

Quick Links

Our 3D Printing Services

What is FDM Printing?

Fused Deposition Modeling (FDM) is a fast, accurate, and cost-effective 3D printing technology that extrudes melted material to create parts.

91MNS’s FDM 3D printing service offers large build volumes up to 914*610*914 mm and a wide range of production-grade thermoplastics in various colors.Materials range from ABS, ABS-M30… (Standard plastic) to PC,NYLON 12… (Engineering plastics) and PEI materials (ULTEM 1010, ULTEM9085, Antero 800NA, Antero 840CN3), NYLON 12 CF and other high-performance materials.

FDM is ideal for creating durable and resistant functional parts, such as jigs, fixtures, molds, and tooling, as well as for medical tissue engineering, rapid prototyping, and production applications.

What is Polyjet Printing?

PolyJet 3D Printing offers one of the most advanced industrial 3D printing solutions. 91MNS’s PolyJet technology is capable of creating smooth surfaces, thin walls and complex geometries with extremely high tolerances of 0.1mm. Technologies that support multiple material choices, can simulate rubber materials of different durometers, multi-color 3D printing, transparent or translucent parts, and simulate overmolding.

Multi-color prints

Achieve complex shapes

Multi-material 3D printing

500+ Thousand Colors Available

Mixed printing of various soft and hard materials

3D prints in as soon as a business day

MJF and SLS technologies were developed by different companies, but they are both based on powder bed fusion 3D printing technology.

These two technologies have high precision, complexity, multi-material printing, internal cavity, and support structure functions, which are very suitable for producing small batches of high-precision products. Although they have differences in printing speed, accuracy, and applicability, they are both high-quality 3D printing technologies that can meet the needs of different industries.

3D Printing Materials

| Material Name | Color(s) | DESCRIPTION |

| ABS-M30 | Black, Ivory | Versatile material good for form, fit & functional applications |

| Versatile material good for form, fit, and functional applications | ||

| Familiar production material for accurate prototyping | ||

| ABS-ESD7 | Black (electrostatic dissipative properties) | Static-dissipative with target surface resistance of 104 ohms (typical range 105 – 103 ohms)2 |

| Makes great assembly tools for electronic and static-sensitive products | ||

| Widely used for functional prototypes of cases, enclosures, and packaging | ||

| ASA | Black, Ivory | Build UV-stable parts with the best aesthetics of any FDM material |

| Ideal for production parts for outdoor infrastructure and commercial use, outdoor functional prototyping and automotive parts, and accessory prototypes | ||

| ABS-M30i | Ivory, White | Biocompatible (ISO 10993 USP Class VI)1 material |

| High Strength, Sterilizable Material | ||

| perfectly suited for medical, pharmaceutical and food-packaging | ||

| PC-ABS | Black | Features high dimensional stability and colorless transparency |

| Certified for five medical approvals including cytotoxicity, genotoxicity, delayed type hypersensitivity, irritation and USP plastic class VI | ||

| Ideal for applications requiring prolonged skin contact of more than 30 days and short-term mucosal membrane contact of up to 24 hours | ||

| PC | White, Black | Most widely used industrial thermoplastic with superior mechanical properties, and heat resistance |

| Accurate, durable and stable for strong parts, patterns for metal bending and composite work | ||

| Great for demanding prototyping needs, tooling, and fixtures | ||

| PC-FR(V0) | light gray | Kimya PC-FR is a polycarbonate FDM 3D printing material with flame-retardant properties |

| highly suitable for passenger rail and air transportation applications | ||

| Kimya PC-FR merges the benefits of polycarbonate, including dimensional stability, high impact resistance, and a wide operating temperature range, with flame-retardant properties. | ||

| PC-ISO | White | Biocompatible (ISO 10993 USP Class VI)1 material |

| Sterilizable using gamma radiation or ethylene oxide (EtO) sterilization methods | ||

| Best fit for applications requiring higher strength and sterilization | ||

| Nylon12CF | Black | Carbon-filled thermoplastic with excellent structural characteristics |

| Highest flexural strength | ||

| Highest stiffness-to-weight ratio | ||

| Nylon12 | Black | The toughest nylon in additive manufacturing |

| Excellent for repetitive snap fits, press fit inserts, and fatigue-resistance applications | ||

| Simple, clean process – free of powders | ||

| TPU 92A | Black | Accurate elastomer parts with high elongation |

| Superior toughness & abrasion resistance | ||

| Wide variety of applications including flexible hoses, tubes, air ducts & vibration dampeners | ||

| ULTEM 9085 | Black, Tan | FST (flame, smoke, toxicity)-certified thermoplastic |

| High heat and chemical resistance; high flexural strength | ||

| Ideal for commercial transportation applications such as airplanes, buses, trains, and boats | ||

| ULTEM 1010 | Amber (Natural) | Certified food safety and bio-compatibility |

| Highest heat resistance, chemical resistance, and tensile strength | ||

| Outstanding strength and thermal stability | ||

| PEKK | Brown | High heat and chemical resistance |

| Low outgassing and high dimensional stability | ||

| Excellent strength, toughness and wear-resistant properties |

| Type | Materials | Description |

| Rigid Opaque | Vero Pure White, Vero Black Plus, Vero White Plus, Vero Yellow, Vero Cyan, Vero Magenta, Vero Blue | Brilliant color options for unprecedented design freedom |

| Combine with rubber-like materials for overmolding, soft touch handles, and more | ||

| Ideal for fit and form testing, moving and assembled parts, sales, marketing and exhibition models, assembly of electronic components, and silicone molding | ||

| Transparent | Vero Clear | Print clear, tinted, and prototype parts with VeroClearTM and RGD720 |

| Combine with color materials for stunning transparent shades | ||

| Ideal for form and fit testing of see-through parts like glass, consumer products, eyewear, light covers and cases, visualization of liquid flow, medical applications, artistic and exhibition modeling | ||

| Simulated Polypropylene | Rigur (White) | Simulates the appearance and functionality of polypropylene |

| Ideal for prototyping containers and packaging, flexible snap-fit applications and living hinges, toys, battery cases, laboratory equipment, loudspeakers and automotive components | ||

| Rubber-like | Agilus30 (Clear), TangoBlack+ | Offers various levels of elastomer characteristics |

| Combine with rigid materials for a variety of Shore A values, from Shore A 27 to Shore A 95 | ||

| Ideal for rubber surrounds and overmolding, soft-touch coatings and nonslip surfaces, knobs, grips, pulls, handles, gaskets, seals, hoses, footwear, exhibition, and communication models | ||

| Simulated ABS | Digital ABS Plus (Ivory) | Simulates ABS plastics by combining strength with high temperature resistance |

| Enhance dimensional stability for thin-walled parts with Digital ABS PlusTM | ||

| Ideal for functional prototypes, snap-fit parts for high or low temperature usage, electrical parts, castings, mobile telephone casings, engine parts, and covers | ||

| Digital Materials | Predetermined blends of the above materials | Wide range of flexibility, from Shore A 27 to Shore A 95 |

| Rigid materials ranging from simulated standard plastics to the toughness & temperature resistance of Digital ABS Plus TM | ||

| Vibrant colors in rigid or flexible materials, with over 500,000 colors options on the Stratasys J750 | ||

| Available on PolyJet multi-jetting 3D printers |

| Material Name | Color | Other Common Names |

| PA12 GB | Grey/Black | High hardness material |

| PA11 | Grey/Black | High hardness material |

| PA12 | Grey/Black | High hardness material |

3D Printing Tolerance

| FDM General Tolerances | Polyjet General Tolerances | ||

| Tolerance Note | Description | Tolerance Note | Description |

| Productive capacity | With 50+ multimillion printing machines | Selection of color | 500+ Thousand Colors Available |

| Build Size | 914*610*914 mm | Build Size | 500*400*200 mm |

| Highest accuracy | 0.05~0.08 mm | Highest accuracy | 0.02~0.05 mm |

| Minimum layer thickness | 0.127 mm | Minimum layer thickness | 0.014 mm |

| Additional Services | 1 mm | Additional Services | 0.6 mm |

3D Printing Post Processing

Post-processing enhances the appearance and functionality of 3D prints, providing a smooth finish, vibrant colors, or added durability. It’s ideal for visible or functional components but may be unnecessary for rough prototypes or internal parts where aesthetics are not a priority.

Removal of support structures

Painting

Sanding

Screen printing

Polishing process

Thread Inserting

From Prototyping to Production within a month

3D Printing

Fit check and function testing form designs at the early development stages.

Urethane Casting

Enhanced Aesthetic and Functional Models for Mid-Development Phases.

Injection Molding

Guaranteed Production-Grade Parts for Testing, Transitional Production, and Full-Scale Manufacturing.

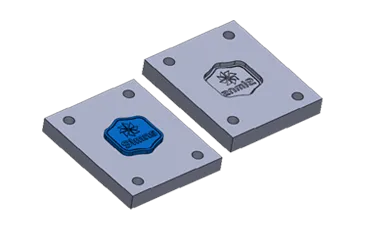

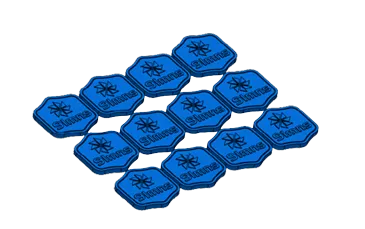

3D Printing Parts Made By 91 MNS

3D Printing FAQs

Q What materials can be used for 3D printing?

Common materials include PLA, ABS, PETG, nylon, TPU, and various metals and resins, each suitable for different applications based on strength and flexibility.

Q How long does it take to print a 3D model?

Print time varies depending on the model's size, complexity, and the printing technology used. Small prints can take a few hours, while larger or more intricate designs may take several days.

Q What are the common applications of 3D printing?

3D printing is widely used for prototyping, product development, custom tooling, medical devices, and even end-use parts across various industries like automotive, aerospace, and consumer goods.

Q Can 3D printed parts be used in functional applications?

Yes, many 3D printed parts can be functional, especially those made from durable materials like nylon or metal, depending on the design and intended use.

Q How do I prepare my model for 3D printing?

Ensure your model is designed correctly in CAD software, check for errors, and export it in a compatible format (like STL or OBJ) before uploading for printing.

Q What is the maximum size for 3D printed parts?

The maximum size depends on the printer's build volume. Most desktop printers have a limited size, but industrial printers can create much larger parts, often exceeding several feet.

Talk to Us About Your New Project!

Get a Quote